Επιδόσεις και ποιότητες των κινεζικών φύλλων χάλυβα πυριτίου

The H series number commonly used in China follows the labeling of Nippon Steel of Japan in the 70s-90s. And now regular manufacturers are labeled according to the new labeling.

Old Marking New Marking Performance Equivalent Material 2019 Price

H12 50H270 50WW270 B50A270 $21,000

H14 50H310 50WW310 B50A310 15800 yuan

H18 50H470 50WW470, B50A470 14000 yuan

H23 50H600 50WW600, B50A600 12600 yuan

H30 50H700 50WW700, B50A700 11000 yuan

H40 50H800 50WW800, B50A800 9600 yuan

H50 50H1000 50WW1000, B50A1000 8500 yuan

H60 50H1300 50WW1300, B50A1300 8000 RMB.

(Annealed sheet is more expensive 1000-2000m/ton)

From the process, Z series are cold rolled oriented high silicon content, H series is generally cold rolled non-orientation of high silicon content, H-type non-orientation of the steel sheet also has a 0.35MM sheet. But the yield is very small, generally used for demanding occasions.

The following types of non-oriented silicon steel sheet are commonly used:

h50 h23 h18 h14 h12

Specific gravity 7.85 7.75 7.65 7.65 7.65

Iron loss P1.5/50HZ≤ 13 6.2 4.7 4.0 3.6

Magnetic flux density B50≥ 1.69 1.66 1.64 1.61 1.6

(According to temperature rise, H18 is lower than H23, H23 is lower than H50, and according to no-load current, it is the opposite. In addition, the same grade has a white piece of black piece, black piece – annealed piece of performance is better than the white piece. (In addition, the same grade core size is different performance is also different)

There are commonly used grades of oriented silicon steel strip:

Z11 Z10

Specific gravity 7.65 7.65

Iron loss P1.7/50 ≤ 1.66 1.51

Magnetic flux density B10 ≥ 1.74 1.77

Translated with DeepL.com (free version)

Silicon steel sheet it is a silicon iron soft magnetic alloy with very low carbon content, generally containing 0.5 to 4.5% silicon. The addition of silicon can increase the iron resistivity and maximum permeability, reduce coercivity, core loss (iron loss) and magnetic aging. It is mainly used to make iron cores for various transformers, motors and generators. Today Hengfeng You Electrical Sales Manager Alisa will take you to see what the performance indicators of silicon steel sheet:

Silicon steel sheet generally with the increase in silicon content, iron loss, punching and magnetic susceptibility to reduce, hardness increases. The higher the operating frequency, the greater the eddy current loss, the choice of silicon steel sheet should be thinner.

1, the requirement of low iron loss of silicon steel sheet:

Low iron loss of silicon steel sheet is an important indicator of the quality of silicon steel sheet, according to the different grades of silicon steel sheet to determine the iron loss of silicon steel sheet, the higher the grade then the lower the value of its iron loss.

2, requires high magnetic susceptibility of silicon steel sheet:

In the motor, silicon steel sheet as the iron core for its operation plays a big role, but different silicon steel sheet has different magnetic susceptibility, we need to choose the magnetic susceptibility of silicon steel sheet as a good material to use.

3, the requirements of the silicon steel sheet surface smooth, flat and uniform thickness:

From the surface texture to judge the performance of silicon steel sheet.

4, require silicon steel sheet has good adhesion and weldability:

In the processing and use of silicon steel sheet in the process, silicon steel sheet on the insulating film adhesion buddy is conducive to anti-corrosion and improve the silicon steel sheet punching.

Summarize: silicon steel sheet iron loss is Hengfeng Friends transformer manufacturers, motor manufacturers concerned about the problem, according to China’s industry standards (GB/3655-2008), the use of Epstein’s square circle or the standard permeability meter (500SST/1000SST) as a test to evaluate the basis of the iron loss of silicon steel sheet, the method is also recommended by the international IEC standards and national standards for the use of the method.

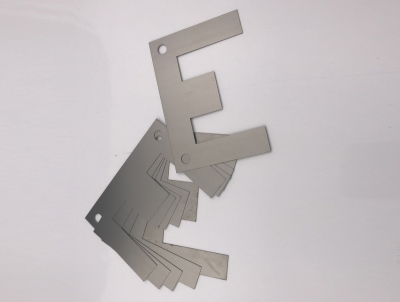

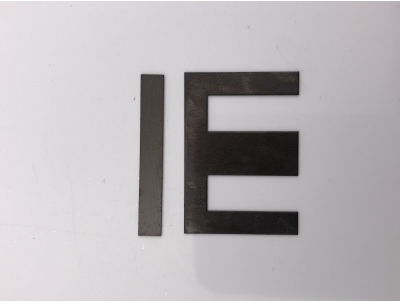

Silicon steel sheet is good or bad depends on the silicon steel sheet material and processing technology, it directly affects the quality of the transformer, processing technology in the stamping method, the annealing method is the most important, the same material of silicon steel sheet stamping burr small and burr large production of transformer performance difference of 7%, the same material of silicon steel sheet annealed (nitrogen protection annealing) and not annealed silicon steel sheet production of transformer performance difference of 7-10%.

Attached 2019 China silicon steel sheet performance and grade control

Japan JFE (old Kawasaki).

35jn250 (0.35mm thick, iron loss between 2.18 and 2.26, magnetic susceptibility of 1.69 or more)

50jn270 (0.50mm thick, iron loss between 2.38 and 2.42, magnetic susceptibility above 1.68)

50jn290 (0.50mm thick, iron loss between 2.46 and 2.51, magnetic susceptibility 1.68 or more)

50jn310 (0.50mm thick, iron loss between 2.50 and 2.54, magnetic susceptibility above 1.69)

Japan Nippon Steel.

50h270 (0.50mm thick, iron loss between 2.37 and 2.41, magnetic susceptibility above 1.68)

50h290 (0.50mm thick, iron loss between 2.46 and 2.50, magnetic susceptibility above 1.68)

50h310 (0.50mm thick, iron loss between 2.49 and 2.53, magnetic susceptibility above 1.69)

China TISCO.

50tw290 (0.50mm thick, iron loss between 2.54 and 2.60, magnetic susceptibility above 1.68)

50tw310 (0.50mm thick, iron loss between 2.64 and 2.69, magnetic susceptibility above 1.68)

50tw350 (0.50mm thick, iron loss between 2.70 and 2.76, magnetic susceptibility above 1.69)

China grade expression:

(1) Cold rolled non-oriented silicon steel strip (sheet)

Expression: DW + iron loss value (at a frequency of 50HZ, waveform sinusoidal magnetic susceptibility peak value of 1.5T iron loss value per unit weight.) of 100 times + thickness value of 100 times. Such as DW470-50 said iron loss value of 4.7w/kg, thickness of 0.5mm cold rolled non-oriented silicon steel, now the new model said 50W470.

(2) Cold Rolled Silicon Steel Strip (Sheet) with Orientation

Expression: DQ + iron loss value (at a frequency of 50HZ, waveform sinusoidal peak magnetic susceptibility of 1.7T iron loss value per unit weight.) 100 times of the value of thickness + 100 times of the value of thickness. Sometimes the iron loss value is followed by G to indicate high magnetic susceptibility. Such as DQ133-30 iron loss value of 1.33, the thickness of 0.3mm cold-rolled silicon steel strip (sheet), now the new model for the 30Q133.

(3) Hot rolled silicon steel plate

Hot rolled silicon steel plate with DR, according to the silicon