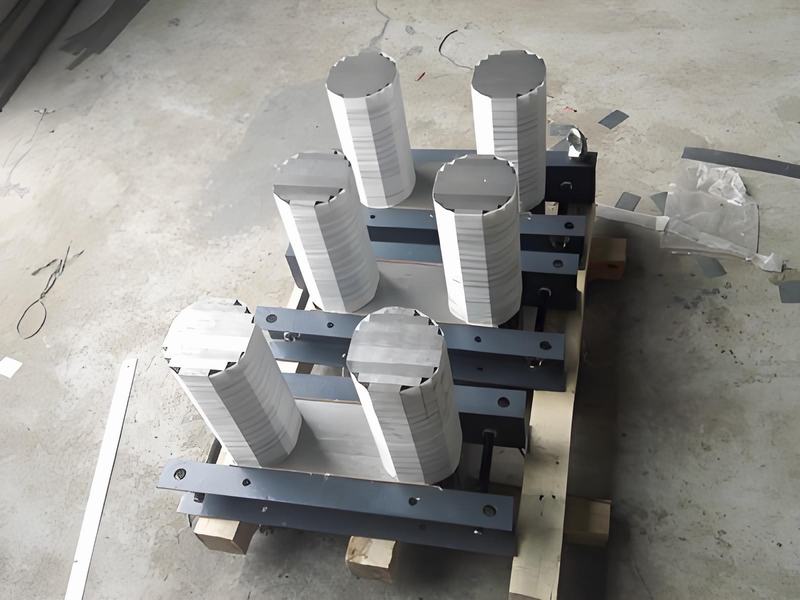

CD-type iron core is made of high flux and low iron loss oriented silicon steel strip winding, vacuum annealed under protective atmosphere, low stress and high viscosity, vacuum dipped paint drying, precision grinding after cutting to ensure better performance recovery, the appearance is mainly divided into two types of single-phase and three-phase, with the advantages of low loss and high magnetic saturation.

| CD type iron core parameters |

| Core model |

50HZ |

400HZ |

| weight(Kg) |

power(A) |

weight(Kg) |

power(A) |

| CD10×12.5×20 |

0.091 |

1.85 |

0.088 |

52.0 |

| CD10×12.5×25 |

0.101 |

2.62 |

0.098 |

63.4 |

| CD10×12.5×32 |

0.115 |

3.81 |

0.111 |

80.5 |

| CD10×12.5×40 |

0.131 |

5.17 |

0.125 |

99.0 |

| CD12.5×16×25 |

0.185 |

8.50 |

0.178 |

106.0 |

| CD12.5×16×32 |

0.207 |

11.70 |

0.199 |

132.0 |

| CD12.5×16×40 |

0.231 |

15.70 |

0.222 |

161.40 |

| CD12.5×16×50 |

0.262 |

20.00 |

0.253 |

197.0 |

| CD12.5×25×30 |

0.332 |

25.10 |

0.320 |

202.0 |

| CD12.5×25×40 |

0.381 |

37.50 |

0.367 |

260.0 |

| CD12.5×25×50 |

0.420 |

46.40 |

0.404 |

313.0 |

| CD12.5×25×60 |

0.477 |

54.40 |

0.460 |

362.0 |

| CD16×32×40 |

0.705 |

77.10 |

0.682 |

427.0 |

| CD16×32×50 |

0.784 |

96.5 |

0.759 |

520.0 |

| CD16×32×65 |

0.903 |

124.0 |

0.875 |

647.0 |

| CD16×32×80 |

1.023 |

150.0 |

0.990 |

764.0 |

| CD20×40×50 |

1.386 |

174.0 |

1.342 |

740.0 |

| CD20×40×60 |

1.507 |

202.0 |

1.463 |

865.0 |

| CD20×40×80 |

1.760 |

268.0 |

1.705 |

1114.0 |

| CD20×40×100 |

2.002 |

329.0 |

1.947 |

1344.0 |

| CD25×50×65 |

2.761 |

396.0 |

2.673 |

1453.0 |

| CD25×50×80 |

3.047 |

474.0 |

2.948 |

1730.0 |

| CD25×50×100 |

3.432 |

580.0 |

3.322 |

2089.0 |

| CD25×50×120 |

3.828 |

684.0 |

3.696 |

2431.0 |

| CD32×64×80 |

5.665 |

906.0 |

5.478 |

2913.0 |

| CD32×64×100 |

6.292 |

1093.0 |

6.094 |

3479.0 |

| CD32×64×130 |

7.227 |

1372.0 |

7.007 |

4294.0 |

| CD32×64×160 |

8.195 |

1661.0 |

7.931 |

5034.0 |

| CD40×80×100 |

11.110 |

1950.0 |

10.791 |

5608.0 |

| CD40×80×120 |

12.10 |

2276.0 |

11.770 |

6487.0 |

| CD40×80×160 |

14.08 |

2898.0 |

13.640 |

8198.0 |

| CD40×80×200 |

16.06 |

3529.0 |

15.620 |

9791.0 |

|

|

|

| Core model |

size m/m |

output power |

| a |

b |

c |

h |

50Hz |

400Hz |

| CD 6.5×12.5×8 |

6.5 |

12.5 |

8 |

8 |

|

5.1 |

| 10 |

10 |

|

7.64 |

| 12.5 |

12.5 |

|

11.9 |

| 16 |

16 |

|

15.2 |

| CD 8×12.5×12.5 |

8 |

12.5 |

10 |

12.5 |

|

24.9 |

| 16 |

16 |

|

34.4 |

| 32 |

20 |

|

43.4 |

| 40 |

25 |

|

53.5 |

| CD 10×12.5×20 |

10 |

12.5 |

12.5 |

20 |

1.2 |

60.6 |

| 25 |

25 |

1.6 |

74.2 |

| 32 |

32 |

2.3 |

94.6 |

| 40 |

40 |

3.0 |

115.2 |

| CD 12.5×16×25 |

12.5 |

16 |

16 |

25 |

5.9 |

123.4 |

| 32 |

32 |

7.9 |

154.9 |

| 40 |

40 |

10.4 |

189.1 |

| 50 |

50 |

13.4 |

299.7 |

| CD 12.5×25×30 |

12.5 |

25 |

20 |

30 |

18 |

221.4 |

| 32 |

40 |

26 |

285.1 |

| 40 |

50 |

34 |

341.5 |

| 50 |

60 |

41 |

398.7 |

|

|

|

|

|

| Core model |

size m/m |

output power |

| a |

b |

c |

h |

50Hz |

400Hz |

| CD 16×32×40 |

16 |

32 |

25 |

40 |

71 |

466.8 |

| 50 |

50 |

94 |

575.4 |

| 12.5 |

65 |

127 |

703 |

| 16 |

80 |

159 |

933 |

| CD 20×40×50 |

20 |

40 |

32 |

50 |

190 |

724 |

| 60 |

60 |

225 |

850 |

| 80 |

80 |

295 |

1073 |

| 40 |

100 |

362 |

1330 |

| CD 25×50×65 |

25 |

50 |

40 |

65 |

427 |

1402 |

| 25 |

80 |

521 |

1678 |

| 32 |

100 |

635 |

2020 |

| 40 |

120 |

796 |

2346 |

| CD 32×64×80 |

32 |

64 |

50 |

80 |

955 |

2696 |

| 32 |

100 |

1135 |

3263 |

| 40 |

130 |

1416 |

3979 |

| 50 |

160 |

1743 |

4800 |

| CD 40×80×100 |

40 |

80 |

64 |

100 |

2010 |

5424 |

| 120 |

120 |

2362 |

6228 |

| 160 |

160 |

3144 |

7908 |

| 200 |

200 |

3749 |

9543 |

|

|

|